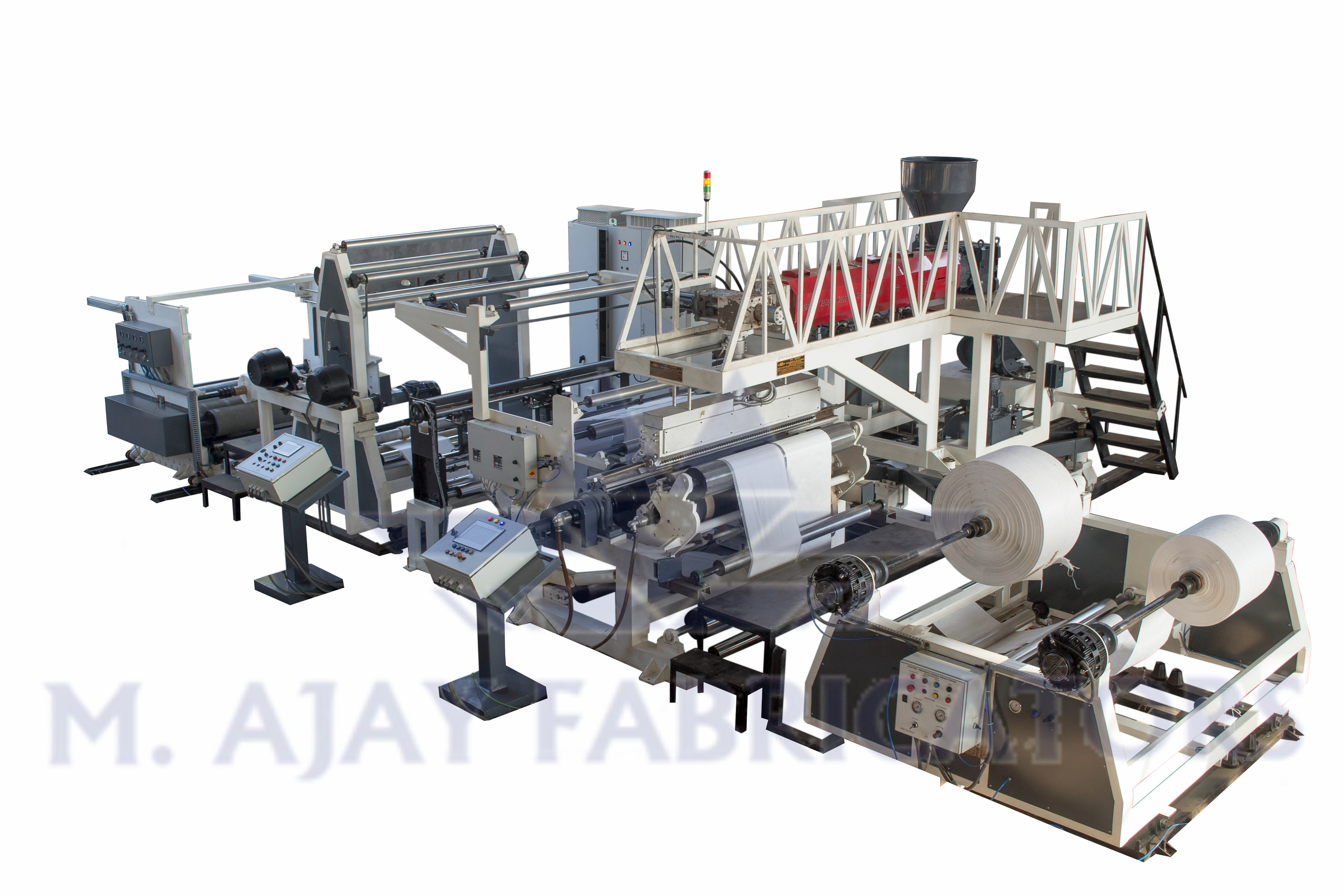

For coating thin layer of polyolefins (Mainly LDPE/PP) on substrates like Paper, Cotton Cloth, Woven fabrics, Non Woven Fabric, Craft paper, Jute fabrics, Aluminium foil, BOPP film, Polyester film, etc. up to 3150 mm Web width applications.

Features

Specialised in fully automatic registration control system for printed BOPP Laminated Woven Bags.

- PLC CONTROLS FOR TOTAL MACHINE OPERATIONS.

- SSR INSTEAD OF CONTACTORS WITH POWER SAVING FUNCTION FOR PRECISE PID CONTROLLED TEMPERATURE CONTROLS.

- TEMPERATURE CONTROL DISPLAY ON HMI TOUCH SCREEN PANELS.

- TOTAL MACHINE PROCESS AND PARAMETERS CONTROLS THROUGH HMI CONTROL PANEL.(TOUCH SCREEN PANELS)

- FULLY AUTOMATIC REGISTRATION CONTROL OF THE PRINTED BOPP ON BOTH THE SIDE BY MEANS OF PRECISE TENSION CONTROLS, COLOUR MARKS SENSORS AND SOFTWARE.

- “RE” – ITALY , MAKE TENSION CONTROL ELECTRO PNUEMATIC BRAKES AS WELL AS PRECISE MAGNETIC PARTICLE BRAKES FOR PERFECT TENSION CONTROL OF THE WEB BY MEANS OF LOADCELL FEEDBACK.

- THIRD GENERATION CONTROL PANELS WITH FACILITY OF PROGRAMMABLE PROCESS RECIPE SETTINGS AND SAVING FOR DIFFERENT KIND OF LAMINATION JOBS CARRIED OUT ON THE MACHINE.

- COLD START PREVENTOR FOR EXTRUDER SAFETY.

- ALARM FACILITY FOR ANY TYPE OF COMMUNICATION ERROR, MACHINE ERRORS, HEATERS FUSED OUT, THERMOCOUPLE MALFUNCTION, MOTOR OVERLOAD ETC.

- HELICAL GEAR BOXES FOR EXTRUDER, LAMINATOR, WINDER ETC.

- ALL AC FREQUENCY DRIVES WITH SYNCRONISED SYSTEM WITH CLOSE LOOP SYSTEM WITH ENCODER/ LOADCELL FEEDBACK.

- TWO STATION SURFACE WINDER WITH ONLINE SPLICING ARRANGEMENT.

- TURRET UNWINDER / REWINDERS WITH AUTO / MANUAL SPLICING FACILITY.

- SUPER FINISHED CHILL ROLLER OF LAMINATOR FOR BETTER GLOSS OF THE LAMINATE. MATT FINISHED CHILL ROLLER FOR PAPER APPLICATION ALSO AVAILABLE.

- HYDRAULIC OPERATED SCREEN CHANGER FOR EASY OPERATOR FRIENDLY CHANGE OVER OF SCREEN PACKS.

- HYDRAULIC OPERATED PRESSURE ROLL SYSTEM OF LAMINATOR INSTEAD OF PNUEMATIC SYSTEM FOR BETTER BONDING AND ADHESION PROPERTIES.

- CENTRE GUIDED WEB ALLIGERS FOR BOPP SANDWICH LAMINATION.

- SANDWICH UNWINDER ON GROUND LEVEL.

Specification

| Model | MAF/75 /LAMINATION |

MAF/90 /LAMINATION |

MAF/100 /LAMINATION |

MAF/110 /LAMINATION/ |

| SCREW DIA | 75 | 90 | 100 | 110 |

| L/D | 30 | 30 | 30 | 32 |

| MAIN MOTOR(KW) | 30 KW AC MOTOR | 45 KW AC MOTOR | 56 KW AC MOTOR | 75 KW AC MOTOR |

| EXTRUDER OUTPUT (KG/HR) | 120-130 Kgs | 180-210 Kgs | 230-250 Kgs | 325-350 Kgs |

| EXTRUDER UP/DOWN | PROVIDED | PROVIDED | PROVIDED | PROVIDED |

| EXTRUDER FORWARD/REVERSE | PROVIDED | PROVIDED | PROVIDED | PROVIDED |

| SCREEN CHANGER | HYDRAULIC | HYDRAULIC | HYDRAULIC | HYDRAULIC |

| T’ DIE (COAT HANGER TYPE) | 1350/1600 MM | 2000/2200 MM | 2650 MM | 3300/4000 MM |

| UNWINDER | TWO STATION MECHANICAL UNWINDER | TWO STATION MECHANICAL UNWINDER | TWO STATION MECHANICAL UNWINDER | TWO STATION MECHANICAL UNWINDER |

| WEB ALLIGNER | PROVIDED | PROVIDED | PROVIDED | PROVIDED |

| LAMINATOR UNIT | ||||

| CHILL ROLL (DIA X L) | 500 X 1350/1600 | 500 X 2000/2200 | 500 x 2650 | 500 x 3300/4000 |

| CHILL ROLL DRIVE(DC – KW) | 3.7 KW | 5.5 KW | 7.5 KW | 11 KW |

| PRESSURE ROLLER | HYDRAULIC OPERATED | HYDRAULIC OPERATED | HYDRAULIC OPERATED | HYDRAULIC OPERATED |

| WINDER | TWO STATION SURFACE WINDER WITH ONLINE SPLICING ARRANGMENT | TWO STATION SURFACE WINDER WITH ONLINE SPLICING ARRANGMENT | TWO STATION SURFACE WINDER WITH ONLINE SPLICING ARRANGMENT | TWO STATION SURFACE WINDER WITH ONLINE SPLICING ARRANGMENT |

| PREHEATING HOT PLATE | OPTIONAL | OPTIONAL | OPTIONAL | OPTIONAL |

| SECONDARY UNWINDER | PROVIDED | PROVIDED | OPTIONAL | OPTIONAL |

| TURN BAR | PROVIDED | PROVIDED | OPTIONAL | OPTIONAL |

| MANUAL EDGE TRIMMING | PROVIDED | PROVIDED | PROVIDED | PROVIDED |

| OPERATING SPEED | 120 MTR/MIN | 100 MTR/MIN | 80 MTR/MIN | 70 MTR/MIN |